Sustainability: Environmental Protection

Company's Leadership and Commitment

The top management of Fook Tin Technologies Ltd. (FT) has long been committed to sustainable development (SD) as a corporate strategy. In the past few years, the Company has committed to and succeeded in continuously improving our performance in SD including that of the environment (EMS) and hazardous substance process management (HSPM).

The Development of an Effective Environmental Management System

Fook Tin has been certified in ISO14001 since 2002 and, we are the first company in the world to be certified in IECQ QC 080000 Hazardous Substance Process Management (HPSM) on Green Process Supplier and Manufacturing Certification and the European Directive 2002/95/EC "RoHS" and 2002/96/EC "WEEE" requirements in 2006. We evaluate and identify environmental aspects that affect our activities, products or services at least once a year. The environmental aspects were prioritized according to the significance of their environmental impact and controlled accordingly. Annual programs with specific objectives and targets are . implemented to manage those significant environmental aspects.

Examples of Improvement in Environmental Performance

Prevention of Air Pollution

Fook Tin invests in measures to reduce air pollution including the removal of paint particles and volatile organic chemicals (VOC) from the automatic painting facility, the elimination of fire extinguishers containing ozone-depleting substances and the installation of environmentally friendly air conditions.

Also, we improved indoor air quality of by implementing a Smoke-Free Workplace Program. Elements of the program include:

- Definition of smoke free areas

- Implementation of program as it applies to employees and visitors

- Proper attitude to smokers

- Smoking and health education

- Smoking cessation education

Fook Tin is awarded the Grand Award of 2004 Hong Kong Smoke-Free Workplace Leading Company Awards. The award was jointly organized by the Hong Kong Council on Smoking and Health, Radio Television Hong Kong and Business Environment Council.

Prevention of Water Pollution

Our Shenzhen manufacturing facilities are located in Level 1 and 2 water conservation zones. Our industrial wastewater is kept to a minimum by innovating on our production process and recycling its use.

Prevention of Noise Pollution

Noise pollution is evaluated, measured, monitored and controlled using noise abatement facility or hearing protection facility-wide in all workshops that generates noise at a level that warrants control. Noise affecting the neighborhood is also monitored and controlled.

Reuse, Recycling and Waste Management

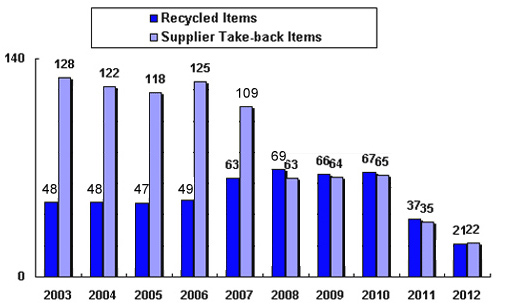

On an ongoing basis, we identify, categorize, collect, arrange and monitor the recycling of waste and items that can be returned to suppliers. All waste is monitored, and specific methods are developed for proper disposal, reuse and recycle.

The following graph depicts the distribution of solid and liquid waste collected or recycled annually:

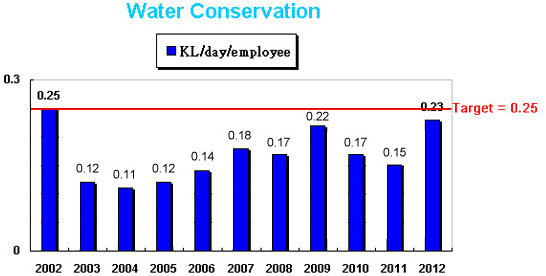

Water Conservation

Similarly, we identify water-intensive operations, and we implement management programs to minimize water use and monitor our performance annually.

Separately, we have in operation environmental programs to address each of the following:

- Hazardous Substances in Products and Processes including but not limited to RoHS and WEEE compliance

- Eco-product Design

- Green Supplier Management

- Green Office/Workplace Program

© 2024 Fook Tin Technologies Ltd. Powered By myID Limited